Submitted by Adeline Nicol on Wed, 03/06/2020 - 14:23

Glassy springs are so much better.

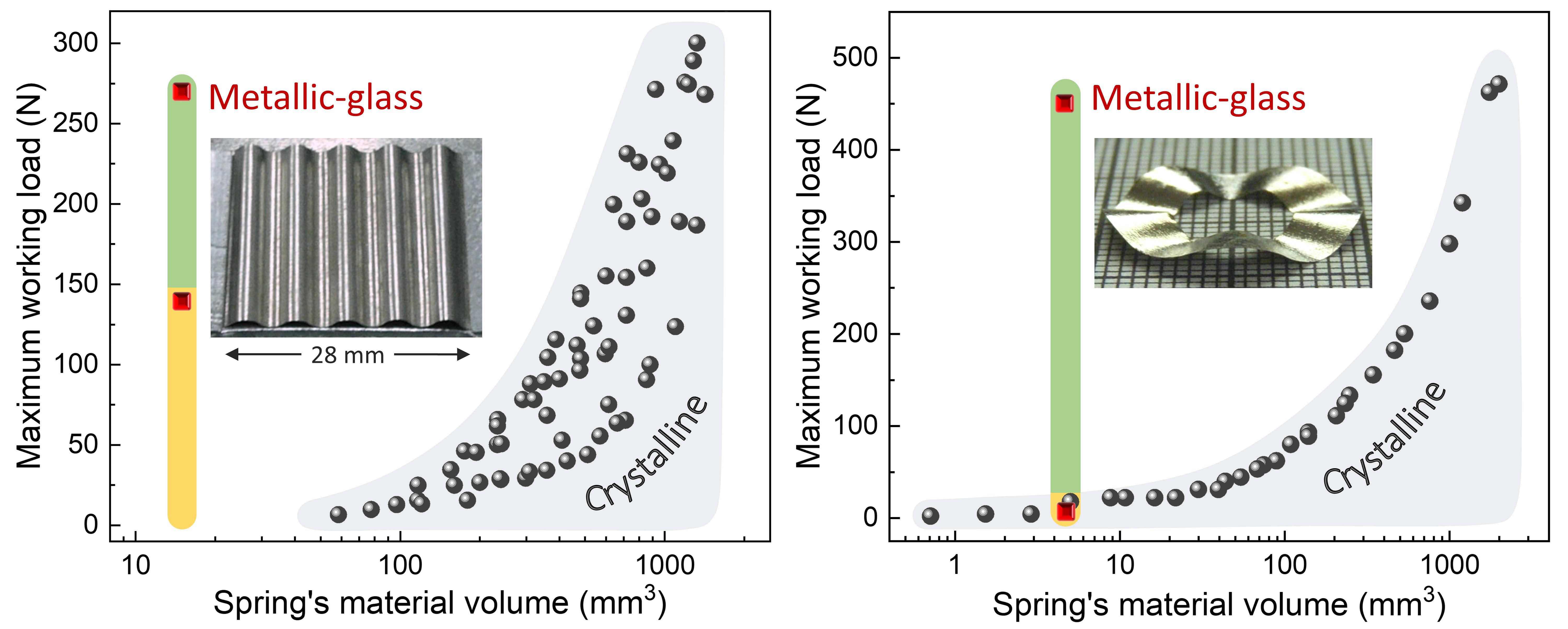

Familiar springs are wires formed into coils but, in comparison, thin sheets formed into wavy shapes can elastically support a given load in much smaller working volume, using much less spring material. This work of Nikos Panagiotopoulos and Lindsay Greer, together with colleagues in Grenoble (FR), São Carlos (BR) and Cranfield, shows that Fe-based metallic-glass foils are particularly suitable for these wave springs in both linear and annular form. Earlier work by some of the authors found a processing window in which metallic-glass foils can be thermoelastically formed without being embrittled, and this breakthrough is now exploited (see photographs in the figure).

The reversible undulatory behaviour, in which the number of arcs in the wave spring multiplies under load, appears to be unique to wave springs made from metallic glasses, reflecting their unusually high elastic limit. This distinctive behaviour gives a J-shaped load-displacement curve that renders the metallic-glass springs fail-safe even under extreme overload. Within the limited range explored in this work, it is notable that a metallic-glass wave spring can support a working load that is 1.3 million times its own weight, far exceeding the capabilities of conventional polycrystalline wave springs. There is potential for metallic-glass wave springs to give dramatically improved performance in MEMS devices.

Related links:-

Article (open access):"Advanced ultra-light multifunctional metallic-glass wave springs", Materials and Design 192 (2020) 108770

Paper of the Month - June 2020 - Department of Materials Science & Metallurgy

This work is dedicated to the memory of the late Prof. A.R. Yavari who has been an inspirational mentor, colleague and beloved friend to the co-authors.

Authorship:-

AM Jorge Jr

M Aljerf

WJ Botta